Innovation

In confirmation of the unceasing commitment to quality and production precision, F.M.V.’s foundry is equipped with a robotic casting system that ensures an extremely high level of efficiency and consistency in every single casting. This sophisticated mechanism is supported by 18 shell mold machines and three melting furnaces—state-of-the-art tools that enable the production of castings of exceptional quality, responding with utmost precision to customers’ specific requirements.

Simultaneously, the workshop is a true center of technological excellence: broaching machines, pillar drills, and CNC lathes are integrated into a state-of-the-art computerized system, managed by personal computers, which ensures accuracy and speed at every stage of the machining process. Additionally, the workshop utilizes a robotic turning cell, a distinctive feature that is rare in the local manufacturing context and allows for high-quality results while drastically reducing processing times.

Since 2009, F.M.V. has further invested in the modernization of its facilities by adding numerous machining centers, which have increased the company’s production capacity and versatility. Subsequently, a measurement room was established—a strictly controlled environment equipped with advanced instruments such as a DEA measuring table, a durometer, a profilometer, a balancing machine, and various other precision tools that enable constant monitoring of component quality.

In 2017, the company took a further step forward by inaugurating an area dedicated to the assembly and final mounting of components, enabling it to offer customers a finished product that fully meets F.M.V.’s high standards.

Simultaneously, F.M.V. has pursued a targeted strategy of digitalization, enhancing the processes of design and planning through the use of sophisticated software and the implementation of an internal network that integrally manages all technical, quality, and administrative information.

This advanced IT system ensures an optimized workflow, reducing lead times while increasing transparency and data traceability, enabling F.M.V. to respond promptly to market demands and maintain the highest standards of operational excellence.

Sustainability

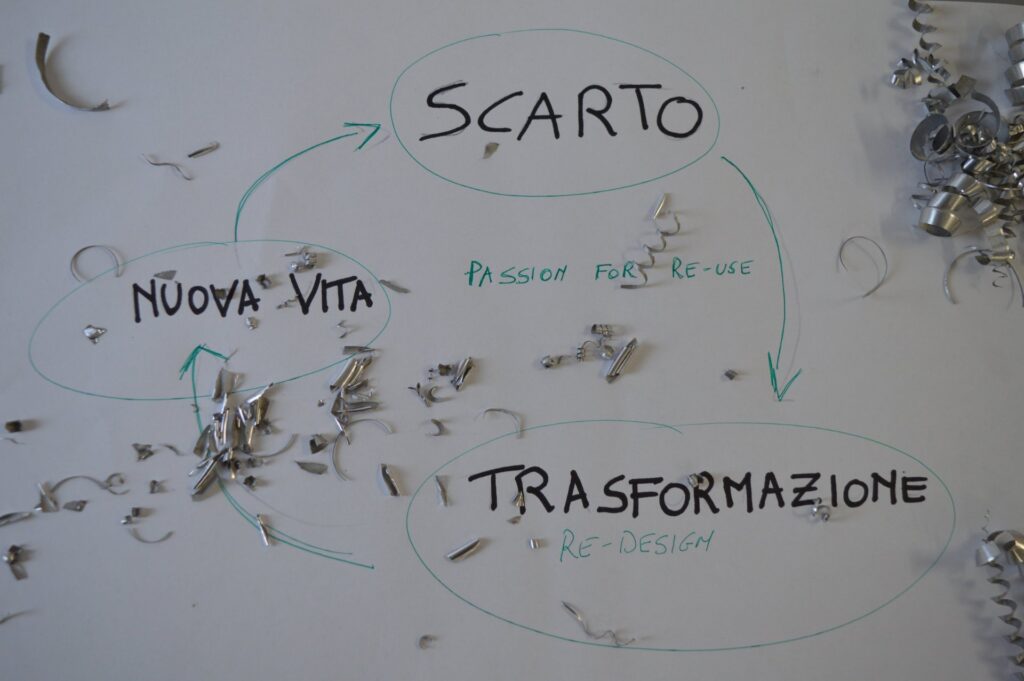

F.M.V. Trasmissioni Meccaniche strongly upholds the values of sustainability, considering them a cornerstone of its corporate mission. The company has integrated an approach of environmental respect and protection into every aspect of its operations, aiming to produce and provide services that safeguard both workers and the surrounding environment. F.M.V. believes this responsible vision not only addresses present needs but also represents a commitment to future generations.

This approach is reflected in its primary goal of fully satisfying customers and all stakeholders, consolidating trust in a company that combines quality, respect, and innovation. To ensure these values translate into concrete practices, F.M.V. has certified its Integrated Management System by adopting the strict UNI EN ISO 9001:2015 and UNI EN ISO 14001:2015 standards. These certifications attest to the high level of quality and the constant attention to the environment, demonstrating the company’s commitment to leaving nothing to chance when it comes to standards of excellence and social responsibility.

In this process, F.M.V. has strengthened its commitment to employing production and management practices that reduce environmental impact, promoting a business development model aligned with the principles of sustainability. The company views this certification not as a final achievement but as a starting point for new initiatives, ensuring harmonious growth that always prioritizes respect for the planet and all the people who contribute to its success.