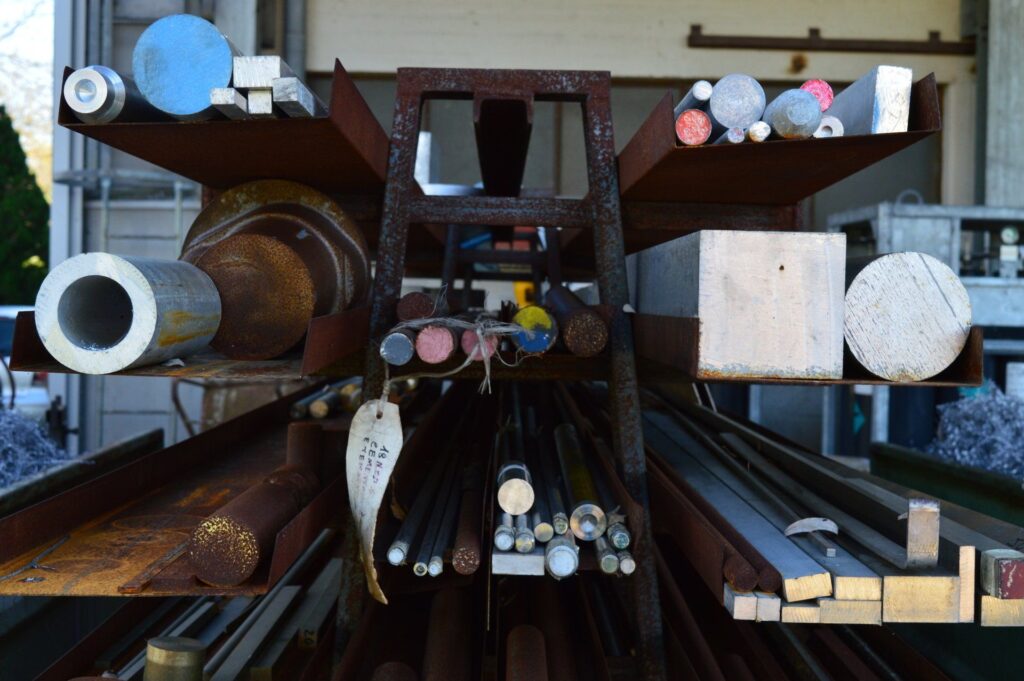

FMV handles a wide range of mechanical machining services, both for in-house products and external components, offering remarkable versatility in the materials processed. In addition to various aluminum alloys, FMV works with numerous other materials, including steel, cast iron, and plastics. To meet these production requirements, the company has a complete range of specialized machinery, including:

Lathes

- Vertical CNC lathes with capacity up to ø 620 mm

- Horizontal CNC lathes with capacity up to ø 450 mm

- CNC lathe equipped with motorized tools and Y-axis, with capacity up to ø 340 mm

- Bar loader with passage up to ø 52 mm

Milling

- Horizontal 4-axis bi-pallet machining centers with maximum travel distances of X:730 mm, Y:730 mm, and Z:880 mm.

Broaching and Shaping

- Broaching machines

- Shaping machines for creating complex profiles

Saws

- Horizontal and vertical saws for precision cutting on various materials

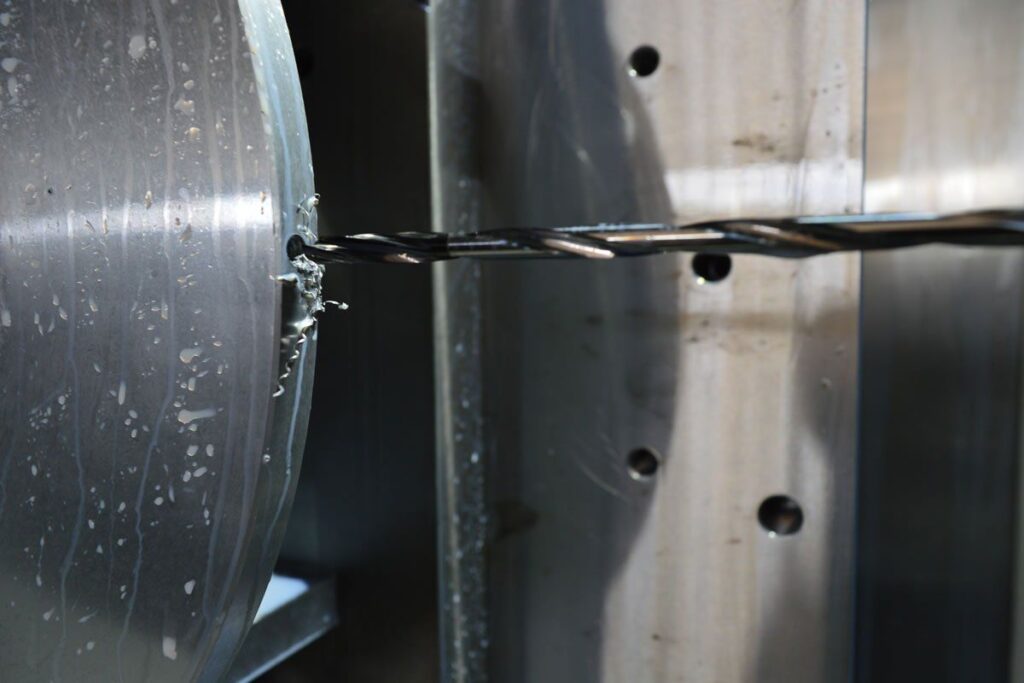

Drills and Other Machinery

- Drills for specific hole-making

- Sandblaster for surface finishing

- Marking machine for component personalization and identification

FMV also operates a traditional mechanical workshop equipped with machines such as lathes, milling machines, and drilling-milling machines. Completing the production cycle, there is an area dedicated to assembly and testing, where components manufactured in-house or received from external suppliers are assembled and functionally tested, ensuring a high standard of quality and precision in the final product.