The company places great importance on quality and is constantly committed to investing in tools and procedures to ensure high standards of precision and reliability. For this reason, it has established a fully equipped quality laboratory, outfitted with advanced instruments to perform rigorous inspections and ensure that every product meets the highest requirements demanded by the market. Among the available equipment, the company includes a state-of-the-art radioscopic system, essential for detailed analysis of the internal structure of materials, as well as a dedicated measurement room, equipped with advanced instrumentation for continuous quality control.

In the quality laboratory, the following measuring instruments are present, carefully selected to meet all inspection and verification needs:

- Durometer: to measure the hardness of materials and ensure the necessary strength for each application.

- Balancing machine: essential to ensure precise balancing of components and minimize unwanted vibrations.

- Go/No-Go gauges: used for verifying dimensional conformity with high precision.

- Infrared thermometer: for accurate temperature monitoring of materials, essential for thermally critical processes.

-

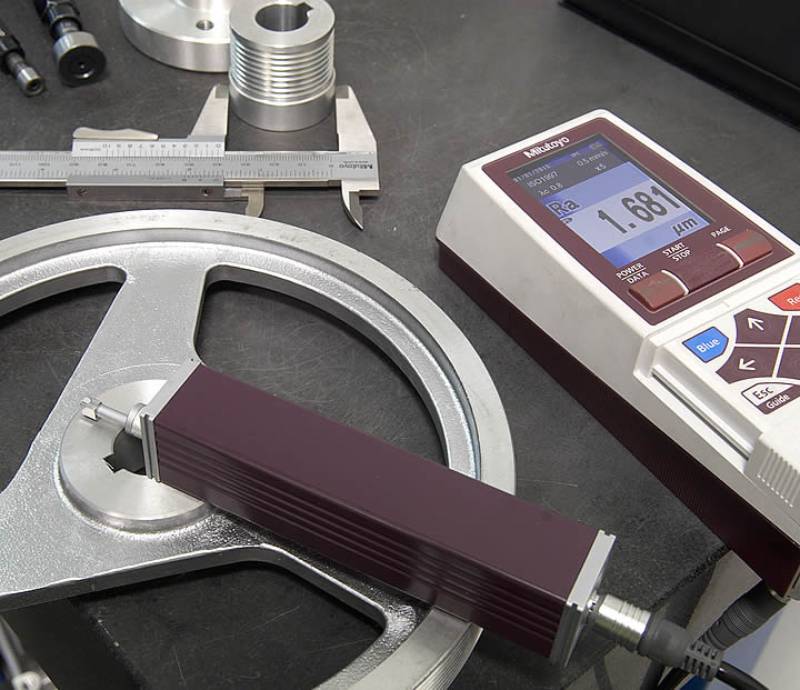

Surface roughness tester:

used to measure surface roughness and ensure finishes meet specific requirements.

- CMM (Coordinate Measuring Machine): for high-precision three-dimensional measurement, used in geometric inspection of components.

-

Radioscopic machine:

used to examine the internal structure of materials, identifying defects invisible to the naked eye.

- Bore gauge: used to accurately verify the diameter and tolerance of holes.

- Digital and analog measuring instruments: for dimensional control using both electronic and traditional methods.

- Micrometer: an essential measuring tool for checking small thicknesses and dimensions.

- Gauge pin: used for calibration tests and dimensional checks of specific components.

- Vernier caliper: a versatile and precise tool for quick measurement of lengths and diameters.

-

Thermocouple:

used for temperature measurements in production processes to ensure compliance with specified thermal parameters.

Thanks to this range of tools, the company can perform meticulous inspections at every stage of production, delivering products that not only meet high standards but also embody a continuous commitment to quality and the fulfillment of even the most complex requirements.